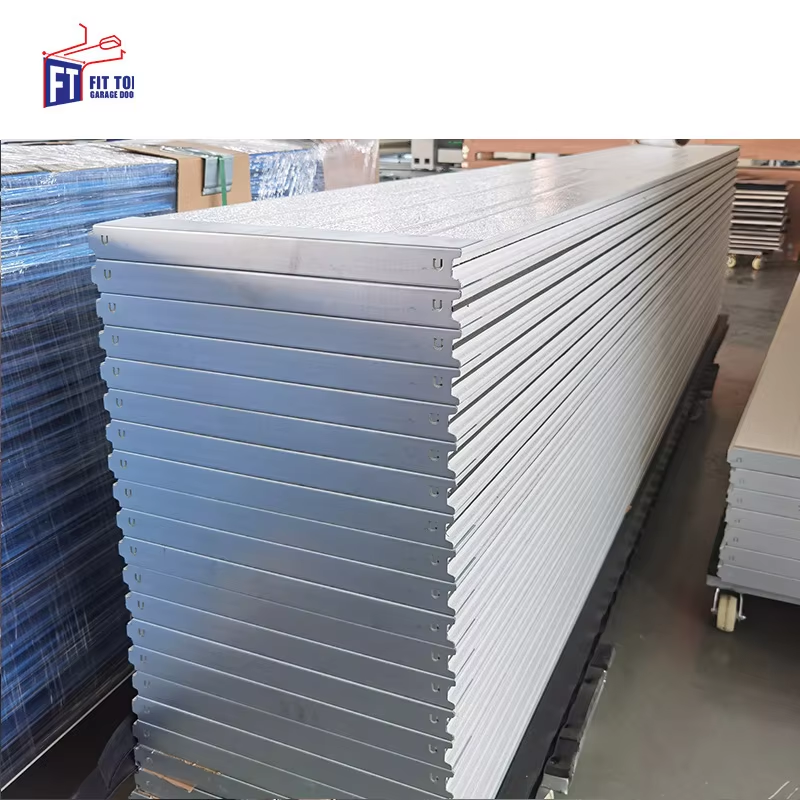

Sectional door panels form the backbone of modern garage door systems, offering superior insulation, durability, and aesthetic appeal compared to traditional single-panel doors. These horizontal panels are connected with hinges and move along tracks, creating an efficient overhead door mechanism. Understanding the various materials used in manufacturing these panels helps property owners make informed decisions about their garage door investments. The choice of material directly impacts performance characteristics including thermal efficiency, maintenance requirements, and overall longevity. Today's manufacturers utilize advanced materials and construction techniques to create panels that withstand harsh weather conditions while providing excellent energy efficiency for residential and commercial applications.

Steel Construction Materials

Galvanized Steel Properties

Galvanized steel represents one of the most popular materials for sectional door panels due to its exceptional strength-to-weight ratio and corrosion resistance. The galvanization process involves coating steel with a protective zinc layer that prevents rust formation and extends the panel's operational lifespan. This material offers excellent structural integrity, making it ideal for large commercial doors and high-traffic residential applications. The zinc coating creates a barrier against moisture, salt air, and environmental contaminants that typically cause metal degradation. Manufacturing processes allow for precise forming of galvanized steel into various panel profiles and thicknesses.

Modern galvanized steel panels feature enhanced coating formulations that provide superior adhesion and longevity compared to earlier technologies. The material's inherent strength allows manufacturers to create lightweight panels without sacrificing structural performance. Advanced forming techniques enable the production of decorative profiles and patterns that enhance aesthetic appeal while maintaining functional excellence. Temperature variations have minimal impact on galvanized steel's dimensional stability, ensuring consistent operation across diverse climate conditions. Quality control processes ensure uniform coating thickness and optimal corrosion protection throughout the panel surface.

Pre-painted Steel Options

Pre-painted steel combines the durability of steel substrates with factory-applied paint finishes that eliminate the need for on-site painting. These sectional door panels feature multiple coating layers including primer, base coat, and protective topcoat systems designed for long-term color retention and weather resistance. The factory application process ensures uniform coverage and proper cure conditions that cannot be replicated in field applications. Advanced paint formulations incorporate UV inhibitors and fade-resistant pigments that maintain appearance over extended periods. Color options range from traditional whites and browns to contemporary architectural colors that complement modern building designs.

The pre-painting process utilizes electrostatic application methods that create strong molecular bonds between paint and steel surfaces. This technology results in superior adhesion and chip resistance compared to conventional painting methods. Environmental considerations drive the development of low-VOC and environmentally friendly paint systems that meet stringent regulatory requirements. Quality testing protocols verify coating thickness, adhesion strength, and color consistency before panels leave manufacturing facilities. Maintenance requirements for pre-painted steel panels are minimal, typically involving periodic cleaning to remove accumulated dirt and debris.

Aluminum Panel Systems

Extruded Aluminum Benefits

Extruded aluminum offers unique advantages for sectional door panels, particularly in applications where weight reduction and corrosion resistance are priority considerations. The extrusion process allows manufacturers to create complex cross-sectional profiles that optimize strength while minimizing material usage. Aluminum's natural resistance to corrosion eliminates the need for protective coatings in many applications, reducing long-term maintenance requirements. The material's excellent thermal conductivity can be advantageous in certain climate conditions, though proper insulation design becomes crucial for energy efficiency. Aluminum panels typically feature anodized or powder-coated finishes that enhance appearance and provide additional protection.

Advanced alloy compositions provide enhanced strength characteristics while maintaining aluminum's lightweight properties. The material's flexibility allows for creative design possibilities including curved sections and custom profiles that meet specific architectural requirements. Recycled content in aluminum manufacturing supports sustainability initiatives without compromising performance characteristics. Installation advantages include reduced structural loading requirements and simplified handling procedures due to lighter panel weights. Thermal expansion properties require careful consideration in design and installation to ensure proper operation across temperature ranges.

Powder Coating Applications

Powder coating technology provides superior finish durability and environmental performance for aluminum sectional door panels. The electrostatic application process creates uniform coverage and excellent edge protection that surpasses liquid paint systems. Powder coatings cure through heat activation, creating cross-linked polymer networks that resist chipping, scratching, and chemical exposure. Color options include metallic finishes, textured surfaces, and custom color matching capabilities for specific architectural requirements. The coating process generates minimal volatile organic compounds, supporting environmental compliance and worker safety initiatives.

Powder coating adhesion to aluminum substrates creates durable bonds that withstand thermal cycling and mechanical stress. Quality control measures ensure proper surface preparation and coating thickness throughout the production process. Advanced powder formulations incorporate UV stabilizers and weathering agents that maintain appearance in harsh environmental conditions. Repair procedures for powder-coated surfaces require specialized techniques and materials to achieve acceptable results. The coating's chemical resistance properties protect against common environmental contaminants including acid rain and industrial pollutants.

Insulation Core Materials

Polyurethane Foam Technology

Polyurethane foam insulation represents the premium choice for thermal performance in sectional door panels, offering superior R-values and structural contribution to panel integrity. The foam injection process creates complete cavity filling that eliminates thermal bridges and air gaps common in other insulation methods. Closed-cell foam structure provides excellent moisture resistance and dimensional stability over extended service periods. Chemical adhesion between foam and steel facings creates composite panel behavior that enhances overall strength and stiffness. Advanced foam formulations meet fire safety requirements while maintaining optimal thermal performance characteristics.

Manufacturing processes utilize computer-controlled injection systems that ensure consistent foam density and complete cavity filling. The foam's expansion characteristics are carefully calibrated to create proper bonding with panel facings without causing dimensional distortion. Temperature stability of cured polyurethane foam maintains insulation performance across wide temperature ranges. Quality control procedures verify foam density, adhesion strength, and thermal conductivity throughout production runs. Environmental considerations include the development of low-global-warming-potential foam formulations that reduce environmental impact.

Polystyrene Insulation Systems

Polystyrene insulation provides cost-effective thermal performance for sectional door panels while offering good moisture resistance and dimensional stability. The material's cellular structure traps air to create insulation properties, though performance levels typically fall below polyurethane foam systems. Manufacturing processes involve cutting polystyrene blocks to precise dimensions for insertion between panel facings. Adhesive bonding systems secure the insulation while maintaining thermal continuity throughout the panel assembly. Quality grades range from standard expanded polystyrene to high-performance extruded versions with enhanced properties.

Installation techniques ensure proper fit and thermal performance while minimizing air gaps that reduce insulation effectiveness. The material's compressive strength contributes to overall panel rigidity, though mechanical properties are lower than foam-filled alternatives. Recycled content availability supports sustainable construction practices without significantly impacting performance characteristics. Fire retardant additives enhance safety properties while maintaining thermal insulation capabilities. Long-term performance studies demonstrate stable insulation values over typical door service lifespans when properly installed and protected from moisture intrusion.

Composite and Advanced Materials

Fiberglass Reinforced Panels

Fiberglass reinforced composite materials offer unique advantages for specialized sectional door panel applications, particularly where corrosion resistance and design flexibility are paramount. The composite construction combines glass fibers with polymer matrices to create materials with exceptional strength-to-weight ratios and resistance to environmental degradation. Manufacturing processes allow for complex geometries and integrated features that would be difficult to achieve with traditional materials. UV resistance properties maintain appearance and structural integrity under prolonged sun exposure. Chemical resistance characteristics make fiberglass panels suitable for industrial environments with corrosive atmospheres.

Advanced resin systems provide enhanced impact resistance and thermal stability compared to standard polyester formulations. The material's electrical insulation properties offer advantages in applications near electrical equipment or in environments where electrical conductivity could pose safety concerns. Color integration throughout the material thickness eliminates concerns about surface coating damage and provides long-term appearance retention. Repair procedures utilize standard fiberglass techniques, allowing for field restoration of damaged areas. Manufacturing flexibility enables custom panel designs that meet specific architectural or functional requirements.

Wood Composite Technologies

Wood composite materials combine natural wood aesthetics with enhanced durability and dimensional stability for premium sectional door panel applications. Advanced manufacturing processes utilize wood fibers, particles, or strands combined with synthetic binders to create materials that resist warping, splitting, and moisture damage. Factory-applied finishes provide weather protection while showcasing natural wood grain patterns and textures. The material's thermal properties offer good insulation characteristics, though additional core insulation may be required for optimal energy efficiency. Sustainability considerations include the use of recycled wood content and low-formaldehyde adhesive systems.

Quality control measures ensure consistent density, moisture content, and dimensional stability throughout production runs. Surface preparation and finishing techniques create durable protective barriers against moisture intrusion and UV degradation. The material's workability allows for custom millwork details and decorative elements that enhance architectural appeal. Maintenance requirements include periodic inspection and refinishing to maintain weather protection and appearance. Environmental certifications verify responsible sourcing and manufacturing practices that support green building initiatives.

FAQ

What factors should I consider when choosing sectional door panel materials

The selection of sectional door panel materials depends on several key factors including climate conditions, intended use, budget constraints, and aesthetic preferences. Steel panels offer excellent durability and security for high-traffic applications, while aluminum provides corrosion resistance in coastal environments. Insulation requirements vary based on geographic location and energy efficiency goals, with polyurethane foam offering superior thermal performance. Consider maintenance requirements, as some materials require periodic refinishing while others maintain appearance with minimal care. Professional consultation helps evaluate specific application requirements and local building code compliance.

How do different insulation materials affect energy efficiency in sectional door panels

Insulation materials significantly impact the energy efficiency of sectional door panels, with polyurethane foam providing the highest R-values per inch of thickness. Polystyrene insulation offers good thermal performance at lower cost points but typically requires greater thickness to achieve comparable results. The continuous insulation provided by foam injection eliminates thermal bridges that can occur with batt or board insulation systems. Air sealing around panel edges and between sections is equally important for overall thermal performance. Professional energy audits can quantify actual performance benefits and potential utility cost savings.

What maintenance requirements apply to different sectional door panel materials

Maintenance requirements vary significantly among different sectional door panel materials, with steel panels typically requiring periodic inspection for scratches or coating damage that could lead to corrosion. Aluminum panels generally need only periodic cleaning, though powder coating may require touch-up in high-wear areas. Wood composite materials may need refinishing every few years depending on environmental exposure and initial finish quality. All panel types benefit from regular cleaning to remove dirt accumulation and periodic lubrication of hardware components. Professional inspection services can identify potential issues before they require costly repairs.

How do environmental conditions affect sectional door panel material selection

Environmental conditions play a crucial role in sectional door panel material selection, with coastal applications favoring aluminum or specially coated steel to resist salt air corrosion. High-temperature environments may require materials with enhanced thermal stability and UV resistance to prevent degradation. Freeze-thaw cycles can affect certain materials differently, making thermal expansion characteristics an important consideration. Industrial environments with chemical exposure may necessitate composite materials or specialized coatings for adequate protection. Local building codes may specify minimum material standards for wind load resistance and fire safety requirements in certain geographic areas.

Table of Contents

- Steel Construction Materials

- Aluminum Panel Systems

- Insulation Core Materials

- Composite and Advanced Materials

-

FAQ

- What factors should I consider when choosing sectional door panel materials

- How do different insulation materials affect energy efficiency in sectional door panels

- What maintenance requirements apply to different sectional door panel materials

- How do environmental conditions affect sectional door panel material selection